Why Sustainable Packaging Boxes is the trend today

The impact of sustainable Packaging boxes design is mostly felt in the marketplace. However, as discussions of sustainability increasingly enter the minds of product managers, various approaches to packaging are being evaluated for overall benefits and further understanding. To gain a deeper insight into this new paradigm, we’ll take a look at three key concerns addressed by sustainable Packaging : material concern, carbon concern, and social concern.

Grow your business by reaching out to a broader audience

Consumer loyalty has always been a challenge in business. As the marketplace continues to expand and the number of competitors increases, companies will have to do more to gain a competitive edge. Brands that can become more flexible, are more likely to succeed in the long run because they are easier to work with and manage.

United capacity

Manufacturers should invest in Sustainable Packaging Boxes. This can be done by using renewable, non-toxic materials to produce new products, which will lower the production costs and help sell those products at competitive rates. additionally, the strategy might help suppliers save costs on shipping and reduce carbon footprint, increasing their profits and providing a better user experience for their customers.

Lower delivering costs

As referenced before, dispatching a little more modest Packaging is an incredible method to rehearse maintainability. A reward to this is it likewise brings down your transportation costs.

Feasible Packaging Strategies

Since you understand what economical Packaging is and what it involves, we should take a gander at the systems and Packaging advancements you can execute to be more eco-accommodating with your Packaging.

In this part, we’ll cover the accompanying techniques:Reused packaging materials

Plant-based Packaging

Plantable Packaging

Compostable and biodegradable plastic are other options

Try not to over-Packaging all through the store network

Use producing accomplices with reasonable practices

1. Reused Packaging materials

Companies often overlook the importance of using recycled packaging, but reusing materials for the creation of your packaging can be a great way to reduce waste and cut costs. Packaging is made from many different types of materials, including paperboard and plastic. Paperboard is especially well-suited as a packaging material because it is lightweight, yet sturdy. Also, you can customize your paperboard boxes to perfectly display your brand.

2. Plant-based Packaging

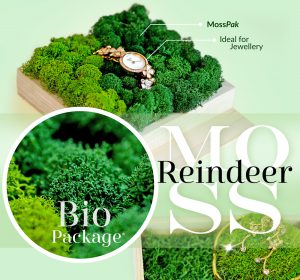

Companies are finding new ways to use plant-based alternatives for their packaging due to the lower cost and more sustainable production process. Bioplastics, for example, are made from renewable resources such as plants, algae, and municipal solid waste. The type of packaging material you choose will depend on your specific product. For instance, if you’re selling food items, you’ll want to ensure the material can protect your products without altering their flavor.

3. Plantable Packaging

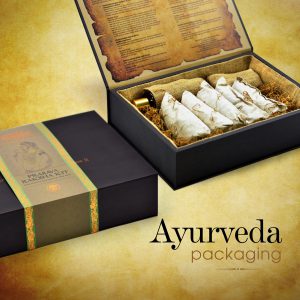

Plantable packaging is a category of materials that can be planted after use. Many businesses have used this technology to package products such as cosmetics and adornments, which often consist of lightweight components. In addition, plantable packaging has been used as a filler or bag material before the product itself is sealed, increasing the level of customer interaction and involvement in the purchasing decision.

4. Compostable and biodegradable plastic are other options

Compostable packaging is made out of materials that can be treated in the soil at home or industrially. They’re frequently produced using a plant-based polymer that can separate in manure. Paper and other green packaging aren’t just great for the environment, they can also save you money. The cost of compostable packaging is less than half that of traditional plastic and paper. The cost of shipping your products just went down.

5. Try not to over- Packaging all through the inventory network

Materials are used to transport products across the supply chain, and many companies use excess packaging to protect items and ensure they arrive safely at their destination. However, this packaging can end up in waste streams, and the cost of making or buying all it adds up. Companies should work with their suppliers to limit unnecessary materials, such as plastic wrapping on small electronics, to reduce waste and save money.

6. Use producing accomplices with maintainable practices

Before agreeing to work with any supplier, it is critical to understand where their products are coming from, how the product is made, and what kind of materials their factories use. If the supplier cannot provide detailed information about their factories, you may have cause for concern. When inspecting a supplier’s factory, look at the factory’s equipment, supplies, and facilities to get a more comprehensive picture of who they are and how they operate.

Related Tags : Custom Sustainable Packaging Boxes, Luxury Eco friendly Packaging boxes, custom eco friendly Packaging boxes, Luxury Sustainable Packaging Boxes